When an oven begins taking noticeably longer to preheat, it can disrupt far more than just cooking time. Slow preheating affects the texture of baked goods, delays meal preparation, wastes energy, and often signals a deeper mechanical issue that requires attention. Two of the most common causes behind this problem are a failing bake element and poor insulation inside the appliance. Both issues impact heat distribution and overall efficiency, but they do so in different ways. Understanding these causes can help you diagnose the problem more accurately and decide whether professional repair is needed.

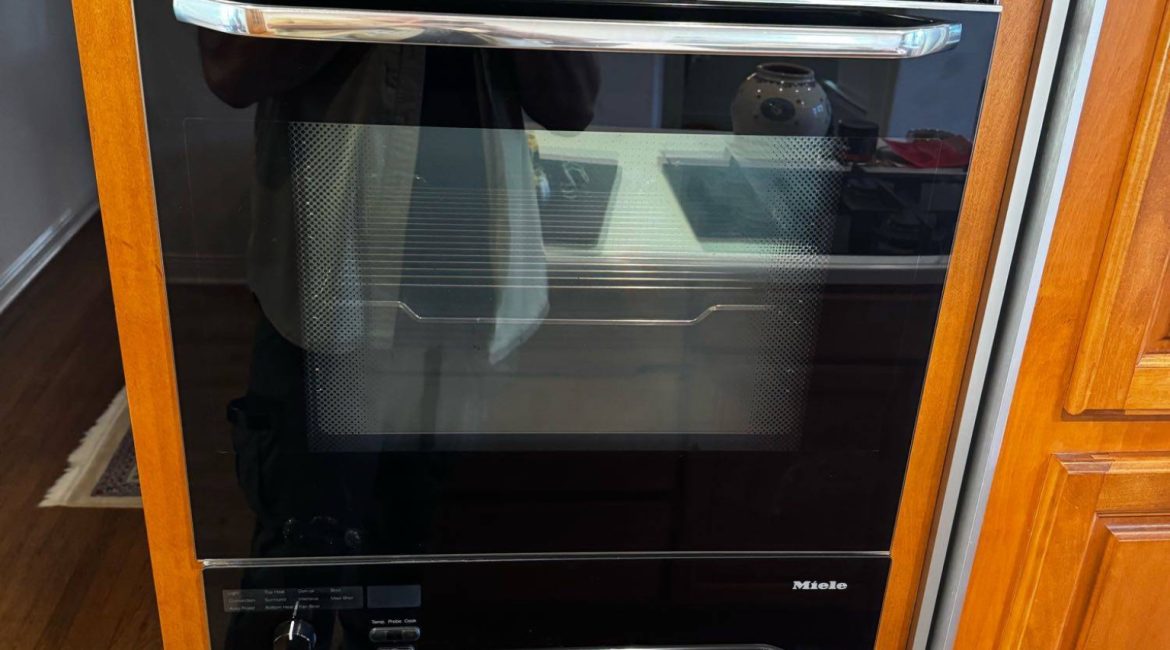

A properly functioning oven is designed to reach temperature quickly and maintain it consistently. When it does not, the first component to evaluate is the bake element. This part is responsible for generating the majority of the oven’s heat, particularly in traditional electric models. Over time, the bake element can degrade, crack, or burn out due to repeated exposure to high temperatures. Even partial failure can drastically reduce heating efficiency. What often starts as slightly slower preheating can quickly escalate into uneven heating, prolonged cooking times, or an oven that stops heating altogether.

A failing bake element usually shows visible signs of damage. The surface may appear blistered, warped, or darkened. In some cases, the element may not glow red as it heats, indicating severe malfunction. While a homeowner can sometimes identify these symptoms through careful observation, diagnosis should ideally be performed by a trained technician. Working with electrical components can be dangerous without proper tools and experience. A professional can test the element, determine whether replacement is necessary, and check for related damage within the wiring system.

If the bake element is not the issue, poor insulation may be to blame. Oven insulation plays a critical role in maintaining consistent internal temperatures. When it deteriorates, heat escapes instead of staying within the cooking chamber. This forces the appliance to work harder and longer to reach the desired temperature. Insulation problems often develop gradually and are less noticeable from the outside. However, common indicators include exterior surfaces that feel unusually hot during operation or a significant drop in oven efficiency.

Insulation damage can occur due to age, frequent high-heat cooking, or previous repairs that required removal of the oven panels. Rodents can also damage insulation in rare cases. Unlike a bake element that is easy to spot visually, damaged insulation is hidden and requires the partial disassembly of the appliance. Replacing oven insulation is a complex job that should always be handled by a professional technician.

Aside from these two primary causes, several secondary factors can contribute to slow preheating. Faulty temperature sensors, malfunctioning thermostats, damaged door gaskets, and issues with the control board can all reduce heating efficiency. A worn gasket, for example, allows heat to escape each time the oven runs, leading to longer preheat times and temperature fluctuations. A faulty temperature sensor can make the oven believe it has reached the correct temperature even though the internal heat level is still too low.

Another factor is user habits. Overloading the oven with cookware during preheating, frequently opening the door, or using outdated baking trays that block airflow can extend preheat times. However, when the oven takes excessively long to reach temperature even when empty and used correctly, you are most likely dealing with a mechanical issue that needs repair.

An oven that struggles to preheat is not simply an inconvenience; it is a sign of decreased efficiency and increased energy consumption. Running an oven longer than necessary leads to higher utility bills and puts additional strain on internal components. A timely repair can prevent further damage and restore proper performance. Homeowners often delay repairs until the appliance stops working completely, but addressing the issue early is both safer and more cost-effective.

If you suspect that your oven’s bake element is failing or that the insulation is no longer effective, professional diagnosis is essential. A qualified technician can quickly identify the root cause, replace damaged components, and ensure the oven operates at peak performance. Attempting to fix these issues without proper training can lead to electrical hazards, incorrect repairs, or further deterioration of the appliance.

Your oven should preheat efficiently and reliably every time you use it. If it has become noticeably slower, it is a clear sign that something is wrong. Do not wait for the situation to worsen or for the oven to stop heating completely. A professional inspection can save time, money, and frustration while extending the lifespan of your appliance.

For fast, reliable, and expert oven repair, contact Poway Appliance Repair Service Center. Our experienced technicians are ready to diagnose the problem, replace faulty components, and restore your oven’s performance quickly and safely. Call today to schedule your repair and get your kitchen running smoothly again.

Contact us